Welcome To MEE

Quality Management

Our Quality Policy

We’re always looking to deliver the best products and solutions to MEE customers, but remain consistent with our proposals, contracts and agreed commitments.

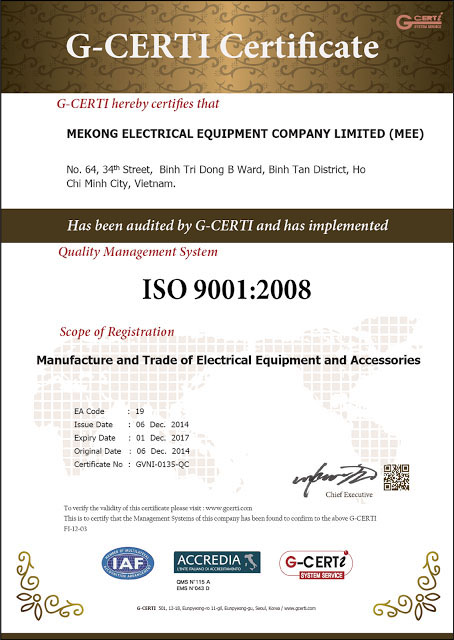

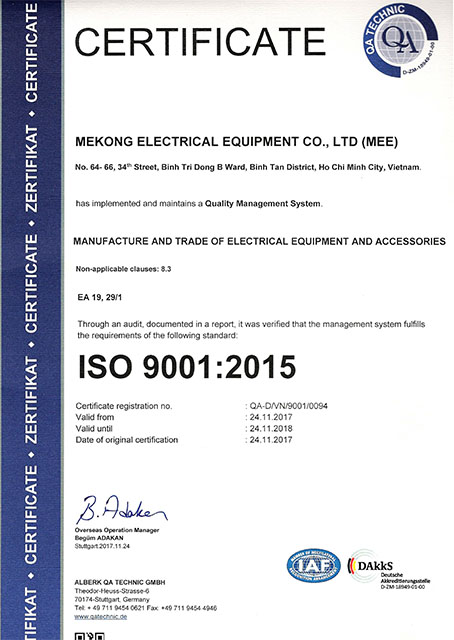

Our system for managing the quality of our products and solutions, and actively promoting a culture of excellence, has achieved the highest endorsement – we’ve been certified to the ISO 9001:2008 Standard and this certification now includes all MEE operation divisions.

Our Quality Objectives

Our Quality Management System sets out to:

- Ensure client satisfaction and build relationships by continually meeting or exceeding agreed requirements. - Consistently deliver quality services and products to our customers by ensuring competent resources and fit-for-purpose systems and processes. - Sustain and improve the competitiveness of the organization by developing our people and continually improving our processes, systems and work practices.

A journey of continual improvement

Under our ISO certification, our quality management system (QMS) is audited on a yearly cycle by our external certifying body. This is supplemented by a robust program of internal audits to continually verify, refine and improve our quality practices. Our program includes regular reviews conducted by our ISO Team, who look at QMS performance and compliance data and make recommendations for improvements, as well as ongoing feedback from our clients and staff, which is complemented by an annual survey conducted by a third party. All insights and issues from audits, reviews, feedback and other sources are managed through our Quality Issues Register to ensure they’re leveraged effectively in the continual improvement of our systems and service delivery.

Our Commitment to Quality

Reliability and durability are engineered into every MEE product. Rigorous procedures ensure accurate manufacturing or co-manufacturing and delivery to the customer. Quality is part of our everyday activities; it is part of our culture, the way we work, and why we take pride in what we do. Our dedication to quality is reinforced by internal processes and procedures, and tools used for quality control and inspection, and supplier quality, including delivery and responsiveness data. MEE’s quality management systems (QMS) requires in-process, final inspection, first article inspection, and product testing to ensure that we meet all quality assurance requirements. Our dedication to quality is not only for our manufacturing facilities but also those of co-manufacturers and suppliers.